Packaging machine for Bruckmayer Mühle

Automation has increased productivity, optimised space and made employees’ work easier.

The Bruckmayer Mill, located in Altötting (Germany), is a producer of high-quality, original Bavarian grains. It frequently finds itself in difficulty to meet the demand for products from the market. Motivated by this, it decided to increase its production capacity but without increasing its staff.

Initially, the idea was to open a new production line related to breakfast products, positioning itself in a high quality market. Only later did the company realise that there were other specific demands, such as producing different types of flour on the German market in different commercial formats, such as:

- wheat flour;

- spelt flour;

- barley flour;

- semolina flour.

In addition, a second need arose, namely that of producing, in two bag sizes, different types of granules:

- cornflakes;

- seed barley; rice:

- puffed rice.

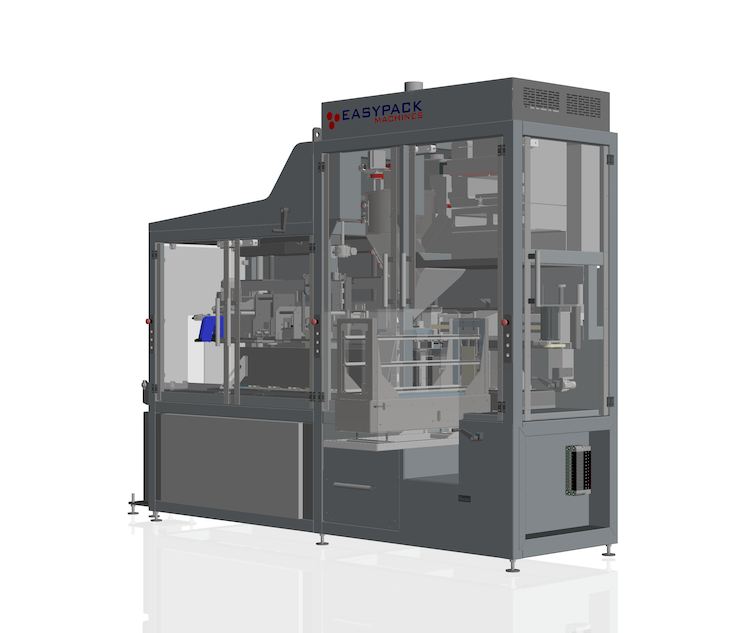

After listening carefully to each individual customer request, the technical department started to carry out various tests that led to the optimal solution: the construction of the B-20 preformed bag packaging machine, which was created specifically for Bruckmayer Mühle. In fact, the machine is equipped with dual dosing technology to ensure a perfect result with both powders and granulates. The bag is closed with a single fold seam. Furthermore, the format range is variable, from 0.5 to 2.5 kg, exactly as our customer wanted.

In this way, the mill produces appropriate storage, which allows it to increase production and reduce the number of personnel in charge, avoiding problems such as workplace accidents and occupational illnesses. All that remains for the operators to do is to load the empty bags onto the machine’s magazine and box them: tasks that require only one supervisor. In addition to customer satisfaction, our machine has also led to optimal results as suppliers are given a bag, of flour or grain, perfectly closed and with the correct amount of product inside, in full compliance with government regulations.

Finally, proper storage of raw materials is guaranteed thanks to the quality and proper sealing of the bags.

Do you have any particular need or request regarding technological integration in your system?

We are glad to provide you with consultation and customized "turnkey" solutions.