Packaging machine for Cromatos

Automation has increased productivity, optimised space and made employees’ work easier.

The customer Cromatos, located in Forlì (FC), is a company dedicated to the formulation and production of dyes, pigments and chemicals for industry, which decided to invest in an automatic machine for filling its products.

Before working with us, the customer used three operators for its bag filling needs:

- one operator would open the bag and roughly fill it;

- the second operator would place the filled bag on a scale and fill it to the desired weight;

- the third operator closed the bag and placed it in the box.

For these reasons, the customer decided to make a specific request of us: to have the possibility of sealing the bags perfectly with a cold application spray glue, which would be activated through the application of heat. Furthermore, in the 5 to 10 kg format, product volumes vary by more than 50 per cent, so it was not possible to use a mechanical filled bag feed system.

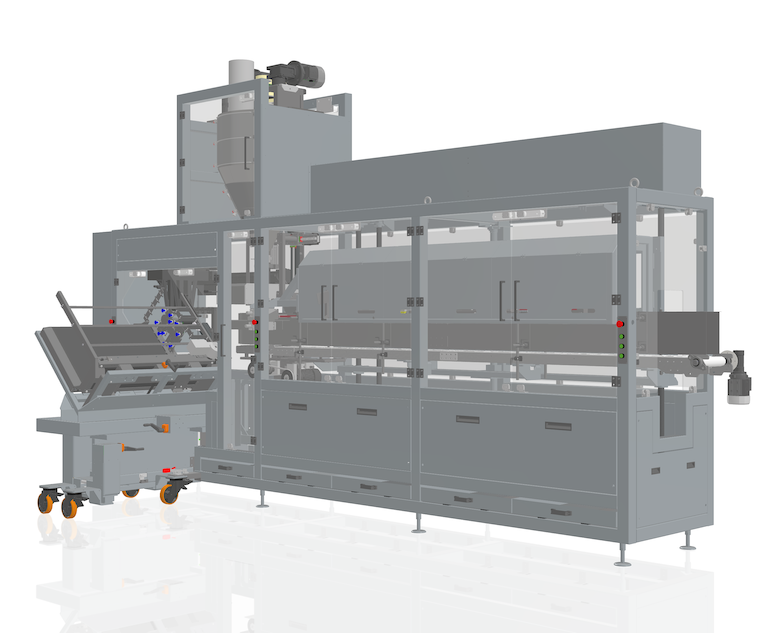

In order to successfully meet the customer’s requirements, the technical department first carried out tests on samples, based on which they developed various mechanical units. After various analyses, it came to the result that a dosing system with bag clamping was to be designed, with a subsequent folding phase on the same station.

Once closed, the bag is taken over by the mechanical closing line equipped with a high-friction conveyor, which in a continuous process removes excess paper, creasing the bag and closing it with a double fold.

Glue application takes place on a moving sack before the glue is activated by heat .

Through this type of investment, the customer was able to immediately cut labour-related production costs, significantly increasing production capacity and accuracy in planning deliveries to the market.

This bagging process has generated great satisfaction with the customer and the operators, who can now take turns in carrying out the activities, as only one operator is needed to steer the machine. The only remaining activities are loading the empty bags onto the machine magazine and boxing. In this way, the customer saves the cost of an operator and increases production capacity by supplying the market with a perfect bag, with a weight and closure that complies with legal requirements.

In the near future, we will also offer the same customer an automatic solution for palletising, in order to improve production planning by interfacing warehouse and ERP.

Do you have any particular need or request regarding technological integration in your system?

We are glad to provide you with consultation and customized "turnkey" solutions.