Packaging machine for Molino Ronci

Automation has increased productivity, optimised space and made employees’ work easier.

In 2021, the customer Molino Ronci, located in Pennabilli (RN), a producer of high quality flour, was in the position of having two people engaged in the packaging process of its flour in 1 kg bags. The only automation used was a self-constructed semi-automatic machine.

The work to which the operators were exposed was divided into several stages:

- an operator would take the bag as it exited the machine and place it on a manual scale, correcting the weight if necessary (adding or removing quantities of flour).

- The bag would then be folded to prepare it for riveting.

- At this point a second operator would take over the sack and rivet it on a second manual riveting station;

- then, he proceeded to form the bundle of 12 packs.

- Finally, before starting production, the bags had to be manually marked with a stamp to indicate the expiry date and production batch.

Among the main reasons that led the customer to the decision to invest in full automation was the need to meet the growing market demand and the need to avoid exposing operators to repetitive manual work, which carries the risk of occupational diseases due to the continuous repetition of the same movements.

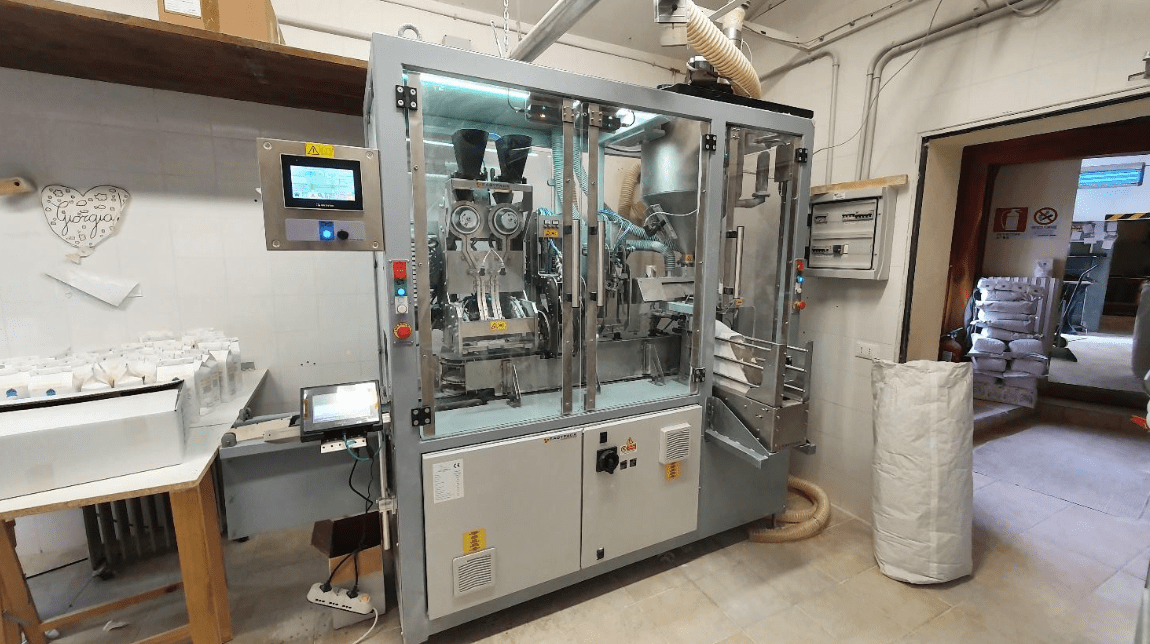

The space available for the installation of the machine was limited, which led us to design an extremely compact tailor-made solution, which contained within it all the automatic functions necessary to automate the bagging process.

In this context, the A-15 project was born, representing an absolute novelty in the sector.

The machine has found its place in the room intended to house the bagging process, to the satisfaction of the customer and the operators who, to date, can take turns in carrying out the activities as only one operator is needed to control the machine.

The only activities left to be carried out are the loading of the empty bags onto the machine’s magazine and the bundle formation, consisting of 12 packs.

We will soon offer the same customer an automatic solution for bundling as well. The machine was purchased under the 4.0 incentives, which were easily solved with our web solution, which integrates the data from the machine and the interface that the operator uses to set the production data. The customer saves the cost of an operator and increases production capacity, providing the market with a perfect bag, with weight and closure that complies with legal requirements.

Do you have any particular need or request regarding technological integration in your system?

We are glad to provide you with consultation and customized "turnkey" solutions.

Do you have any particular need or request regarding technological integration in your system?

We are glad to provide you with consultation and customized "turnkey" solutions.